Oswalds Mill Audio. A strange name for an unlikely story. OMA gets its name from a more than 200 year old mill in Eastern Pennsylvania, restored by OMA founder Jonathan Weiss. You can read the whole story of the mill here. In that mill Jonathan assembled an impressive collection of vintage cinema and studio audio equipment, especially horn loaded loudspeakers, dating back to the 1930's. Within the walls of this massive mill, which has been featured in campaigns for Ralph Lauren, Anthropologie and Victoria’s Secret, Jonathan’s audio obsessions attracted like minded people who congregated there every year for an event which became world famous. This underground community of speaker and horn designers and builders, tube audio and vinyl and tonearm experts became the foundation for launching a whole new approach to high end audio- OMA, Oswalds Mill Audio.

OMA STORY

process

All OMA products are made in the immediate environs of Oswald's Mill in Eastern Pennsylvania. Most are made by hand, though sometimes aided by very high tech engineering. To understand what we make, it's useful to know the processes involved.

Our slate, from which our turntables, plinths, equipment racks and even some amplifiers are fashioned, comes from the last two functioning quarries in Pennsylvania. It is cut on a state of the art five axis water jet machine owned and operated by a Mennonite family, surrounded by Mennonite farms. Once cut, the slate is honed by hand using water and diamond tooling and abrasives.

The hardwoods we use to make our speakers, amplifiers and audio furniture grow in the surrounding forests of Pennsylvania and are sustainably harvested. Our woods typically require years of careful air and then kiln drying, and we also use cutting edge new processes like torrefaction that literally cook the wood to improve its tonality and increase its stability. We have our own 15,000 square foot wood shop with both state of the art CNC machines and also antique woodworking machines and equipment which allow us to build things no one else makes today.

inspiration

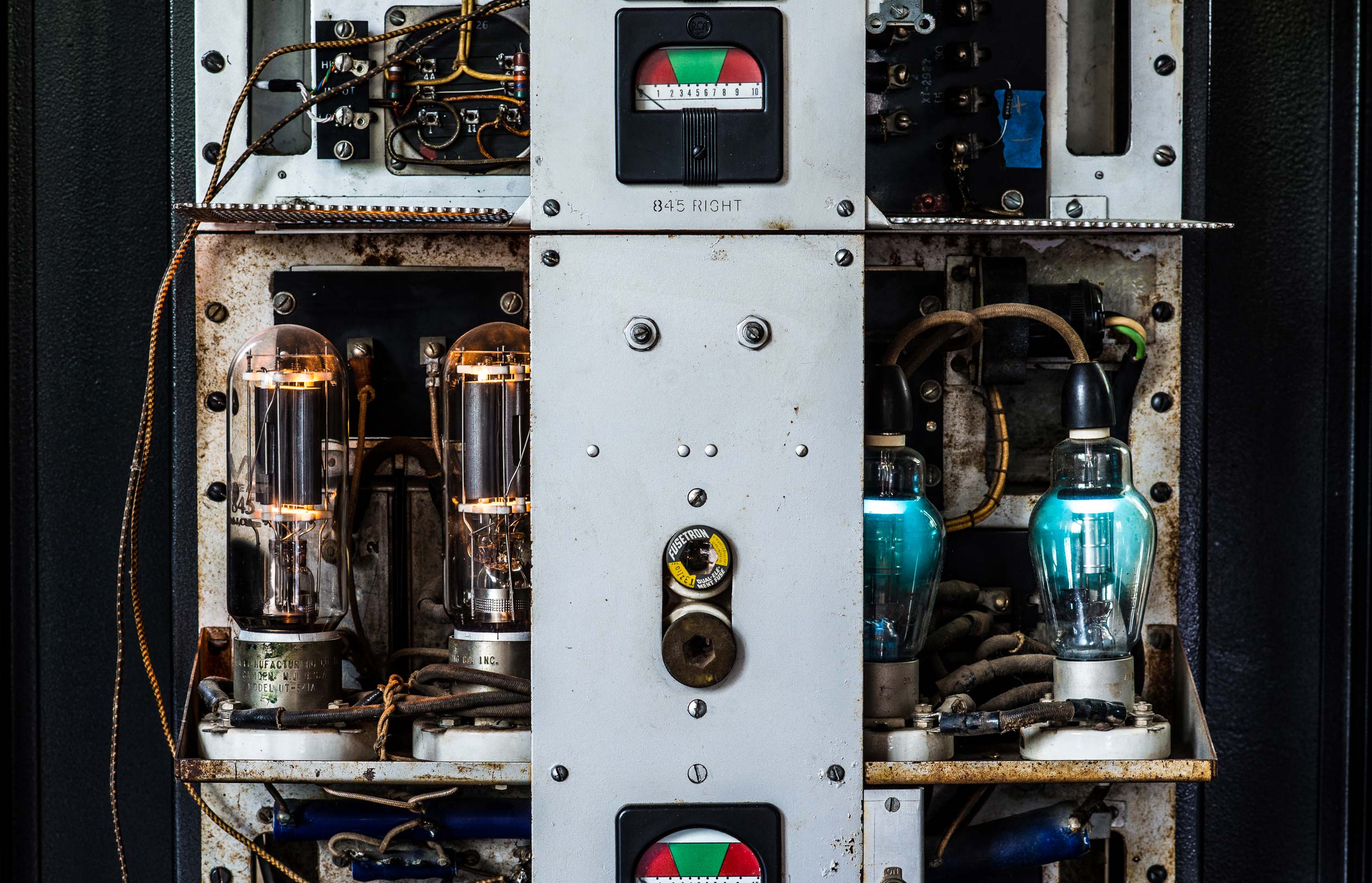

Today Oswald's Mill functions as the lab and reference collection informing the acoustical design and engineering of all OMA products. Our large collection of vintage professional tube amplifiers, speakers and turntables stretching back to the 1930’s allows us a proper standard by which to judge and inspires what we create, using the best ideas and practices from the past.

FSC

In 2019 we started Fleetwood Sound Company, a new division of OMA. We created FSC to produce a new line of smaller, more affordable audio components while retaining the ultra high build quality and design as our OMA line. Loudspeakers with the same solid hardwoods, hand rubbed natural finishes (oil and wax), conical horns and innovative audio engineering driven design made within reach.

Built under the same roof as OMA in Pennsylvania, next to the factory that made the Fleetwood motor car synonymous with "world’s finest".